What are the cycle time and details? Can you tell us about its importance?

Cycle time is one of the most important data that can be obtained from the production site. Unfortunately, even if it seems very simple, mistakes are often made. These errors can be in the methodology and therefore in the values of the cycle time itself.

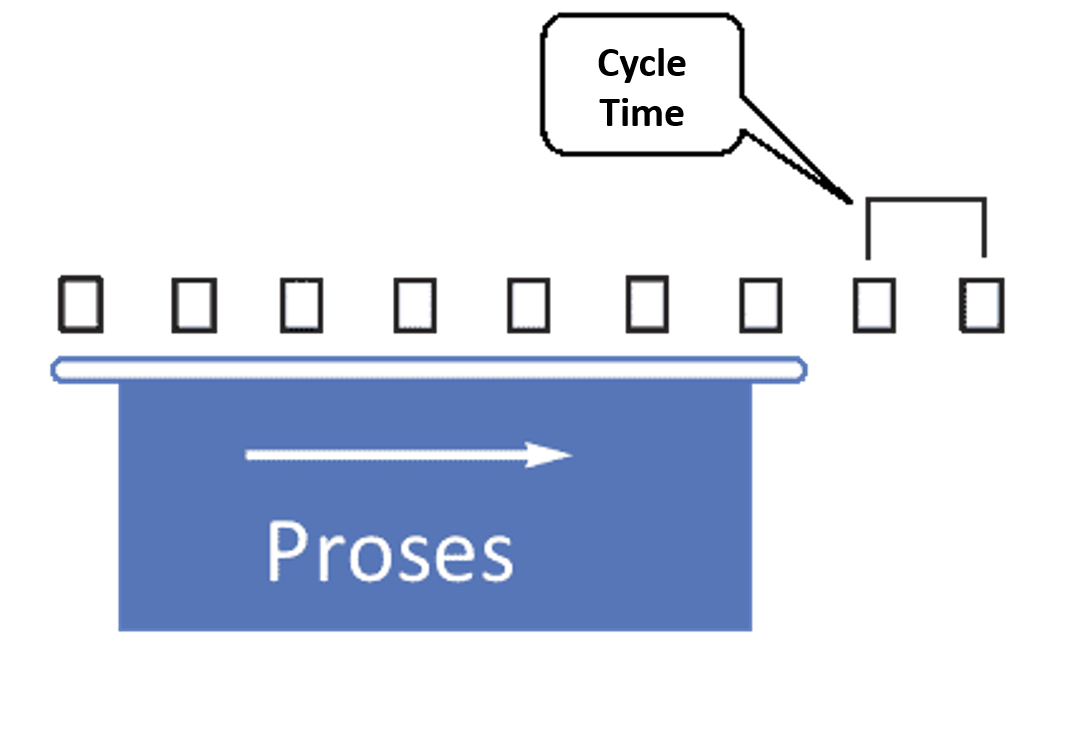

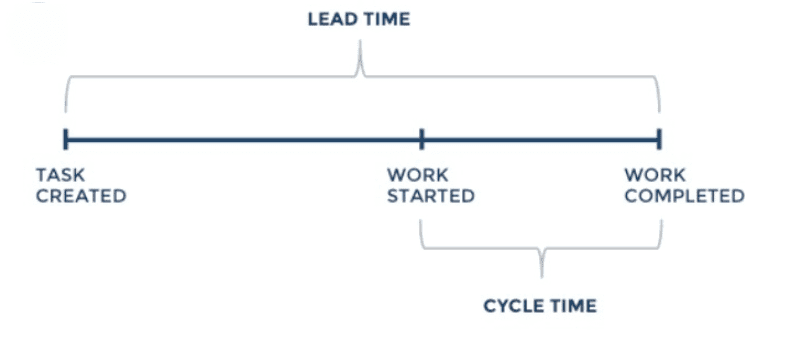

In its simplest form, we call the cycle time the frequency with which a process completes the product it will produce. In other words, the time it takes from the start to start point of a product until a new product arrives to be processed at the same point again. It is easier to understand and calculate for processes that produce a single unit in each cycle. For an operation involving 10 seconds of clamping, 40 seconds of machining and 5 seconds of disassembly, the cycle time will be 55 seconds.

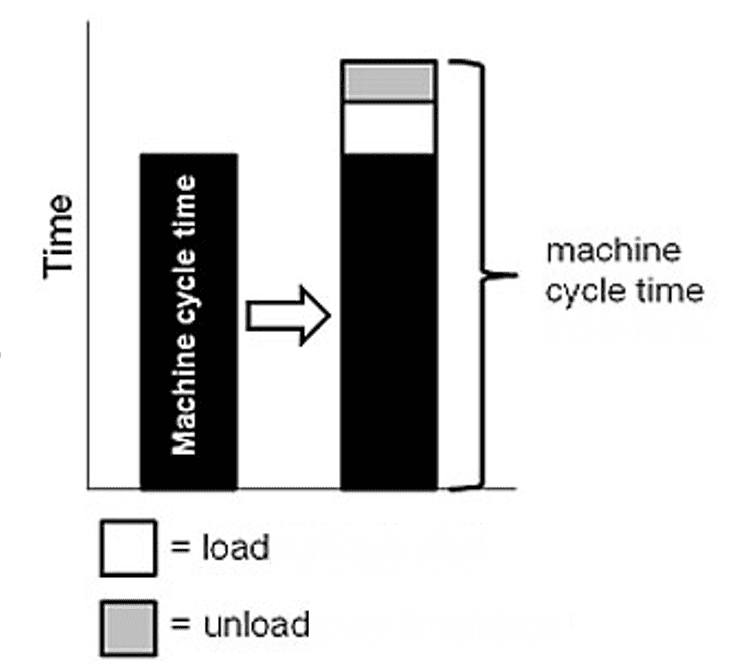

Of course, it is possible to calculate cycle time with a similar approach for cumulative productions. For example, if a dyeing oven takes 20 pieces in each cycle for the product to be measured and 60 minutes is required to complete this batch and move on to the next batch, the cycle time of a product will be 60 minutes / 20 pieces, 3 minutes as a result. It should be noted that whether we are talking about a single unit or a batch, loading and unloading times should not be ignored.

In fact, the cycle time is the maximum time the product spends at the station. In order to analyze and improve it, it would be more appropriate to break it down into sub-units. The first definition is called full cycle time and at the most basic point it can be divided into machine time and operator time. In the classical approach, the sum of these two gives the full cycle time. However, in some processes, this math will not always work, as operators may be engaged in other tasks in parallel during machine automatic time.

In the case of plastic injection molding, where an operator takes the edge burr of the nth product while the machine is pressing the n+1th product, the machine time + operator time will be longer than the full cycle time.

Another point that should be mentioned while talking about the sub-components of full cycle time is the definition of takt time; when the concept of cycle time is researched, the concept of takt time is often encountered and unfortunately these two concepts are often confused and used interchangeably by users in practice. Takt time depends on customer demand. It is calculated as daily available production time / daily customer demand. This value is compared with the cycle time and if the cycle time is higher than the takt time, the customer demand should be met by optimizing the process or increasing resources.

It is a common habit to maximize the use of our equipment investments in order to get the most out of them. But the downside of leaving equipment idle is the problem of not being able to respond to more demand. Even if the order is being met, the predictable result is that teams working hard to meet unreasonable demands will compromise quality.

Proper planning is the first and most important step to avoid such consequences. The right cycle time is the basis for proper planning. While balancing between reducing the cost of keeping stock and increasing demand fulfillment, if we start with cycle times that we are not sure of, we are simply leaving it to chance.

"Good things only happen if they are planned, bad things happen by themselves."

How should cycle times ideally be managed?

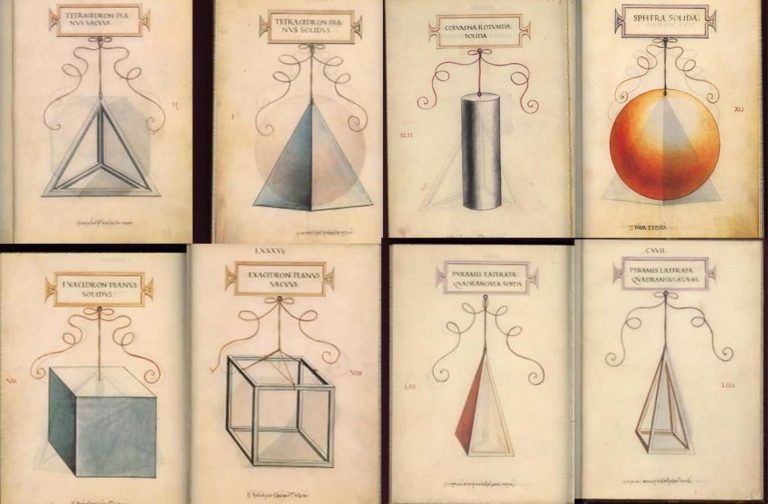

Until the 15th century, mathematical calculations could be calculated with the help of simple geometric shapes (triangles, rectangles, circles, etc.).

The object to be measured was likened to these simple shapes and calculations with high error rates were made. For example, after a river overflowed, the boundaries of the fields next to the river were redefined. The errors were insignificant compared to not being able to measure at all and losing the boundaries of the fields altogether. Or the Basilica cistern and drinking water reservoirs in Istanbul. Enough water was kept for this many people for this many days. The calculation of how many m3 of water there was inside was roughly calculated with circles, squares and triangles. They were calculating with great errors by simulating the architecture of the cistern with simple geometric shapes.

This famous sketch comes from a much earlier Roman architect named Vitruvius, who made it in 1492.

As needs progressed, the tools used became insufficient to solve mechanical problems. The error rates in these calculations were too high. Mechanical problems were unacceptably high.

Living in the 15th century, Leonardo Da Vinci, one of the most important engineers of the period, worked in many fields. He worked in many fields from machine design to architecture and anatomy.

He attached great importance to geometric shapes and frequently used geometric shapes to solve the problems he encountered.

This simple geometry-based calculation was insufficient to calculate the mechanics of non-standard-shaped equipment such as helicopters, three-barreled cannons, automobiles, tanks, organisms, etc. in order to produce those machines and devices.

In the 16th century, the distinction between engineers and mathematicians was not as clear as it is today, as there was no deepening in the disciplines of engineers and mathematicians. More powerful methods of analysis were needed to solve mechanical problems. In the production of steam machines and tools, this calculation with a high margin of error was not enough.

Mathematical calculation methods were developed. New tools were obtained, the most important of which was the derivative-integral, and calculations were made by obtaining the smallest unit that could be found with DL, DS, DV and summing them within limits. It offered great opportunities to engineering and became a tool for development.

So, what are DL, DS, DVs that will allow you to analyze better in your production area? What are the smallest meaningful pieces you can find?

They are your cycle times. Calculating cycle times only in the office with data on paper is like calculating before the 15th century. Large error rates are highly likely. What is calculated on paper is often not the same as what happens in production. When determining your cycle times, the production department must be at the center of the work.

Data is born on the shop floor - to ERP - to BOM - to planning - back to the shop floor with a work order - measured again and the cycle repeats.

How should cycle time analysis be done?

Cycle time has sub-components. While the full cycle time works well for planning, it is even more important to analyze it in sub-categories for improvement efforts. If it is necessary to open the sub-categories, the following headings will emerge;

Effective Machine Cycle Time: Machine cycle time plus loading and unloading time, plus set-up time per unit. The value obtained here is the volume of capacity that must be reserved in the machine for a product.

The known preparation time, i.e. set-up time, is the time it takes to get the work system ready to perform the task and, if necessary, to put the system back in order after the task is finished. It differs from the load-unload time in full cycle time in that it is usually done "once" for each order.

Machine Cycle Time: The time required for a machine to complete all operations on a part, in other words, the time in which the machine and the part are directly related in the cycle.

Operator Cycle Time: When timed by observation, this is the time required for an operator to complete all elements of the work at a workstation before starting to repeat.

Before conducting cycle time analysis in a process, that process must be standardized and defined. A point that is constantly underlined in the lean production approach is that; "It is not possible to measure an undefined value, and it is not possible to improve it without measuring it.

The subject of time study studies within the scope of work study studies is cycle time analysis. The most frequently used method for analyzing the cycle time is the time determination study carried out by measuring directly with a stopwatch in a certain selected time period.

In this case, the accuracy of the data increases as the sample size increases. However, there are two problems that should not be ignored in measurements made with this method. The first is that the perception of being observed by the person doing the work can mislead the measurement. The second problem is that the limited time period causes us to miss variables that depend on the conditions.

Increasing the sample size reduces the margin of error of the second problem, but in this case the power of the measurement will increase considerably. Moreover, the variety of parts to be measured and frequent changes in physical conditions make it very difficult to perform this measurement for all production processes in some enterprises.

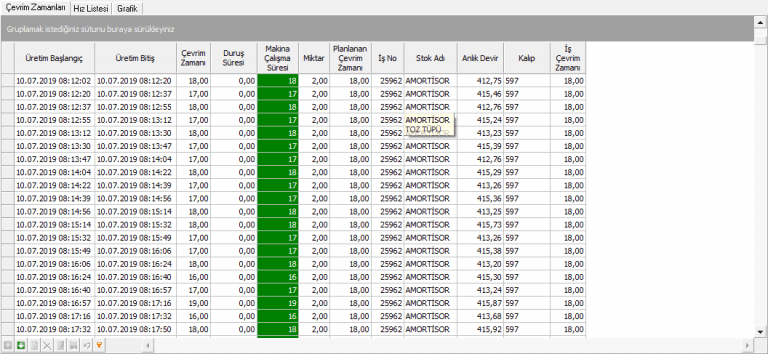

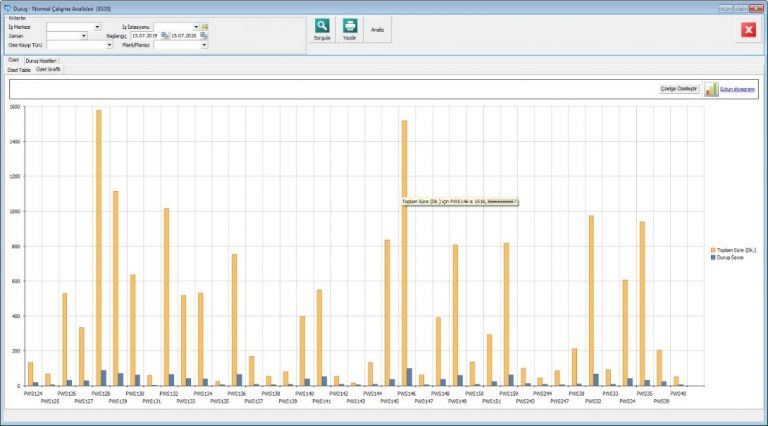

MES Systems enable these analyzes to be done automatically by the system since it monitors the data of the equipment instantaneously and keeps it under continuous recording. The analyzes indicated in the visuals are prepared by the system.

Can SETUP times be improved with cycle time analysis approaches?

Of course they can be improved. Set-up times are a treasure trove for those who want to correct losses in their businesses.

Since the start and end times of each set-up time are recorded accurately, MES users can make improvements in set-up times.

Set-up should also be treated as a process in its own right.

It is necessary to take too many samples to determine the ideal set-up time. When not enough samples are taken, ideal times cannot be determined.

Can you tell us about the importance of cycle times for line balancing?

First of all, we need to explain what line balancing is. Line balancing is to ensure high machine and labor utilization by equalizing the speed of each work equipment.

The output obtained in a specified time unit is called speed. The speed mentioned in cars is actually the same thing. If the specified time unit is an hour, it is talked about how many kilometers per hour it is going, this can be easily converted into cycle time. 1 minute, which is the time it takes for a vehicle traveling at 60 km/h to travel 1 km, can be called cycle time.

The purpose of using the speed unit when this point is so easy to convert to each other is this;

Since it is referred to by the speed unit, it is especially suitable to avoid confusion in continuous production. For example, if we say that the ideal cycle time for cable production is 1 minute, it will not be clear whether this is for a meter, a km or a reel. But when 120 mt/min is said, the same thing is understood by everyone. Now that the speed issue has been clarified, if we go back to the line balancing issue, it is done in order to equalize the speeds of the equipment, but this is quite simple in theory but very difficult in practice. The process to be done;

- Division of work into units

- Determination of standard deadlines

- Calculating the minimum number of workstations

- Balancing the line by distributing to workstations

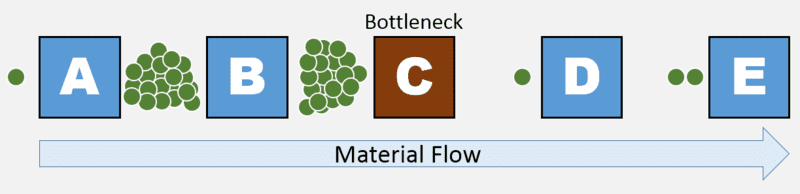

At this point, the stage of dividing the work into units sometimes cannot be kept at the desired level due to the structure of the process and even bottlenecks begin to form.

In the picture, station C is the bottleneck on this line.

These bottlenecks reduce the efficiency of the previous and subsequent equipment, the accumulated stocks cause poor quality production in some cases, increasing the production flow time. In some cases, when a new product is commissioned, due to the structure of the equipment, so much stock accumulates before the bottleneck that it is necessary to take it out of the line with a manual process and then feed it manually.

All these are processes that increase production costs but do not create value, that is, the customer is not willing to pay. Line balancing should not be seen as a one-time job at the initial stage of the line's installation. It may not work at the first planned efficiency due to reasons such as increased model changes, new product commissioning. For this reason, in case of low productivity, the line should be rebalanced by supporting the line with continuous improvement, i.e. kaizen studies.

.png)

With this kaizen, the speed of the line was increased from 40 to 50 pieces per hour.

Cycle time is directly needed for balancing. The more accurate the cycle time used in the initial calculation, the smaller the difference between the planned efficiency and the actual efficiency of the line will be.

One of the most effective methods to measure the success of the kaizen efforts made after the commissioning of the line is to compare the cycle times before and after.

Does improving cycle times only improve the performance parameter of OEE?

Improving cycle times improves the performance parameter of OEE. Only performance? No, it is not.

When the process is standardized with lean logic, the number of defective production will decrease and your quality value will increase. The reasons leading to downtime will be eliminated and your availability rate will increase. In other words, it improves all 3 parameters of OEE: performance, quality and availability.